TEDA have a large inventory of our 2 own storehouses and have 9 cooperative factories with reasonable prices and excellent quality. After testing and certification, we can ensure long-term and stable supply status. In addition to the local factories in Tianjin, there are other places to visit.

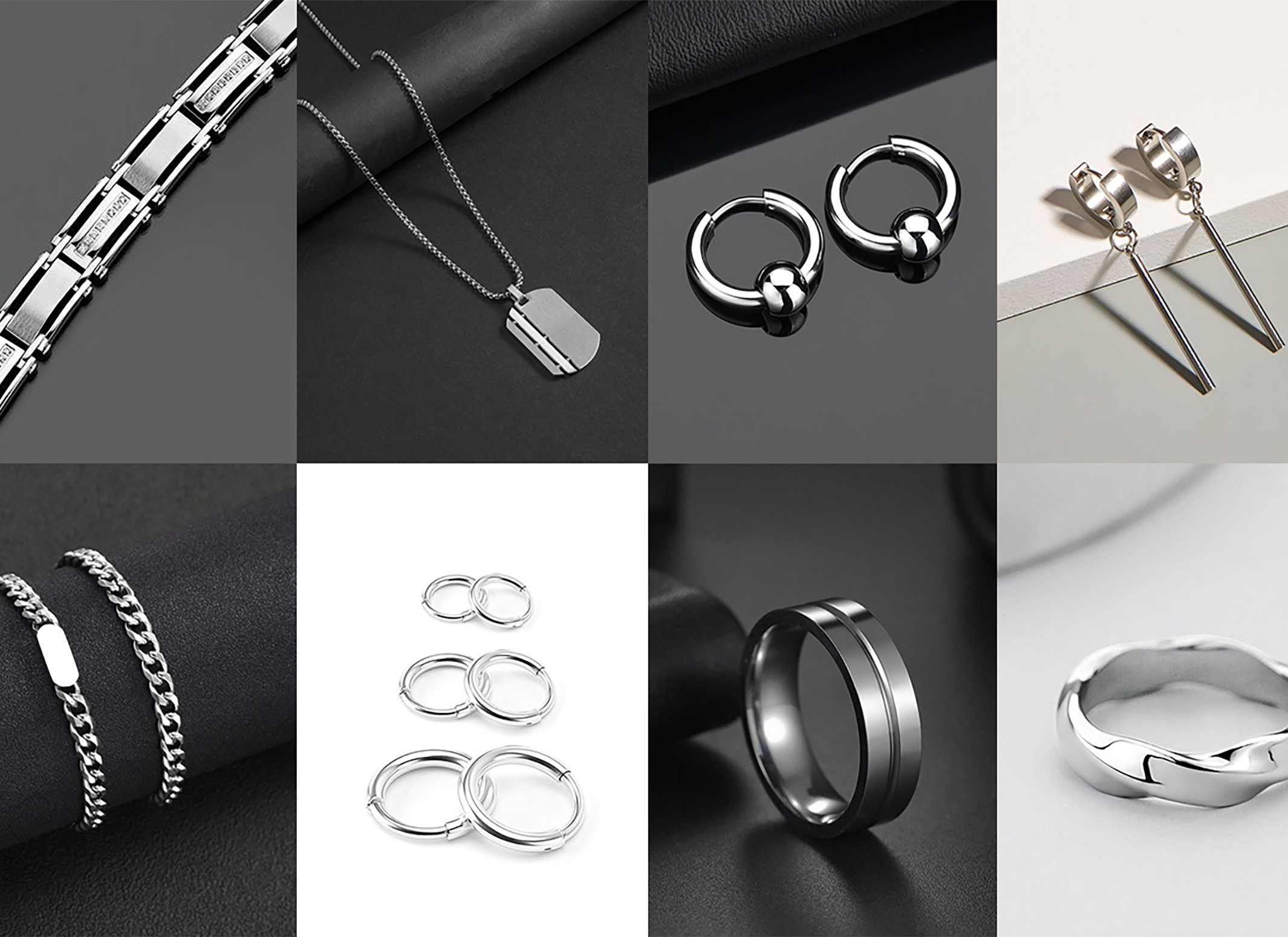

The pursuit of texture and taste of the stainless steel jewelry market.powder metallurgy MIM technology to achieve the production of shaped and complex structures of various types of parts.

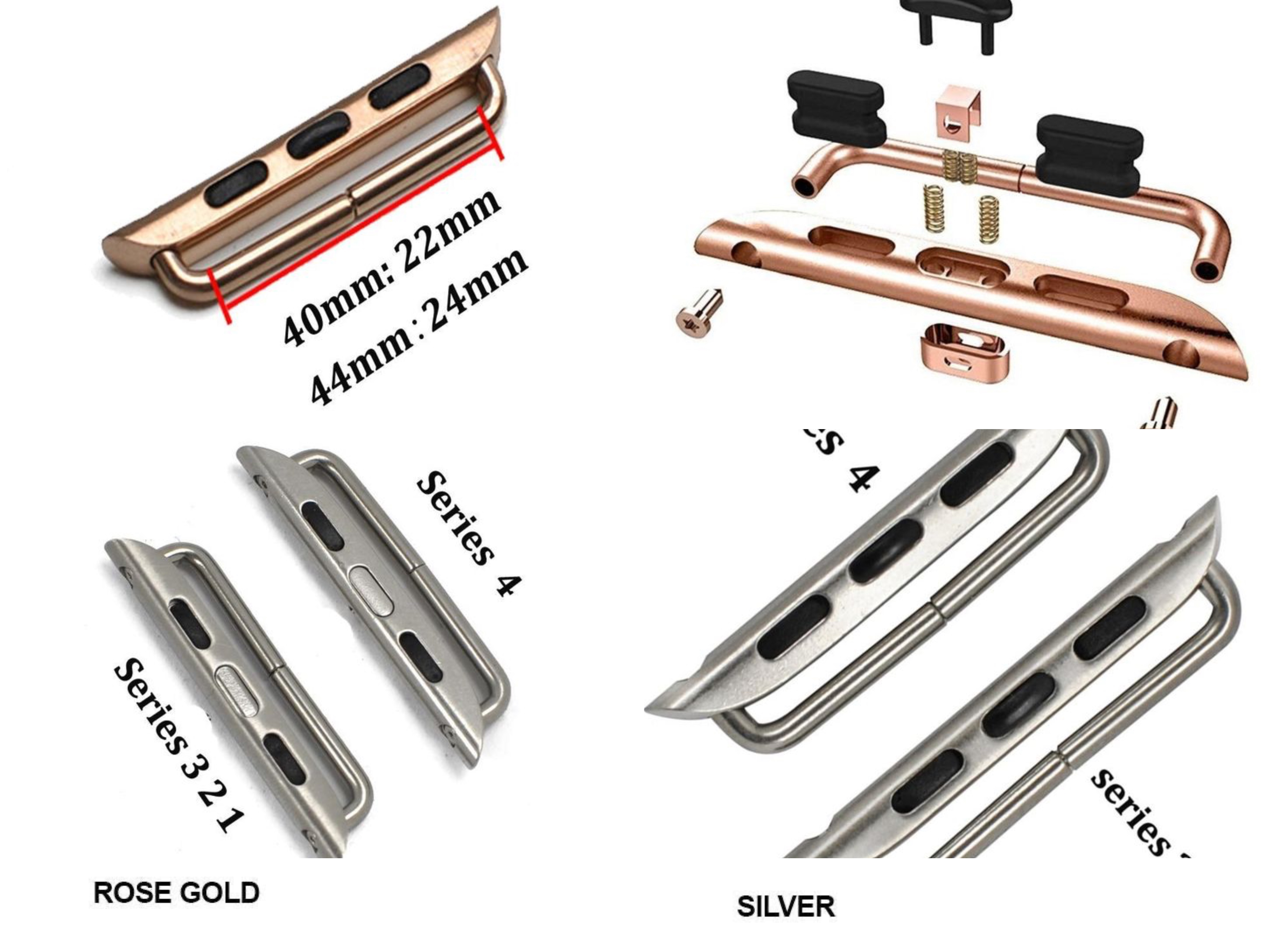

At present, the varieties of powder metallurgy MIM materials in the market demand of watch wearing consumption are still mainly stainless steel, with a market share of 65%, low alloy steel accounting for about 23%, cobalt-based alloy 5%, tungsten-based alloy about 5%, titanium alloy 0.4%

MIM Stainless steel is everywhere in 3C electronic products Traditional consumer electronic Powder Metallurgy products usually include smartphones, tablets, laptops, digital cameras and other hardware devices, while emerging consumer electronic devices include smart wearable devices, drones and so on.

Harber MIM delivery the ripe experiences and solution through MIM process, MIM process has many advantages that other processes can not match. For example, the precision of products made by precision casting is not high, and the surface is very rough.

Products Group

Hot Sale MIM Parts

Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Structural Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical Instrument Parts Harber Industrial Injection Molding Sintering Medical Instrument Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts Harber Industrial Metal Injection Molding Sintering Medical MIM Surgery Forceps Parts, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps Harber Industrial Injection Molding Sintering Part MIM Medical Instrument Surgery Bipolar Forceps, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Precision Metal Injection Molding Sintering Part MIM Medical Accessories Harber Industrial Precision Metal Injection Molding Sintering Part MIM Medical Accessories, MIM (Metal Injection Molding) is applicable to wide range of metal materials including low alloy steel, stainless steel, tool steel, nickel-based alloys,tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy and fine ceramics, etc. More

Copyright © 2010-2022 Harber mim-experts.com All Rights Reserved | Sitemap

Harber Metal firmly believes that quality is the soul of metal parts, and strictly abides by every standard, every process of production, and every detail of service!

Harber MIM, your total metal component solution

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.